HIGH PRECISION-CUT CALIBRATED NATURAL EMERALDS

Authentic

Authentic Cut With Perfection

Cut With Perfection Accurate Specifications

Accurate Specifications Full Colour Spectrum

Full Colour Spectrum Harmonious Clarity

Harmonious Clarity On Demand Availability

On Demand Availability

Color

A full colour spectrum ranging from graded colour tones to fulfil the most demanding designs.

Cutting

Finest quality natural coloured emeralds are crafted to the ideal specifications. Machine cut technology with digital precision of computerised controls is used to attain perfection.

Calibration

Emeralds are graded to the harmonious colour, clarity, size and shape within narrow persistent tolerances and are designed to fit into standard settings. They are also used in watch and jewellery mesh setting equipment.

Our Products

| No | Shape | Sizes | Image |

|---|---|---|---|

| 1 | Round Diamond Cut[ 8/8, 24/16, 32/24 ] | 0.60 mm to 5.00 mm |  |

| 2 | Square Princess Cut | 1.00 mm to 2.50 mm |  |

| 3 | Marquise Cut | 4*2 mm and up |  |

| 4 | Baguettes | 2*1 mm and up |  |

| 5 | Emerald/Single Stone | On Demand |  |

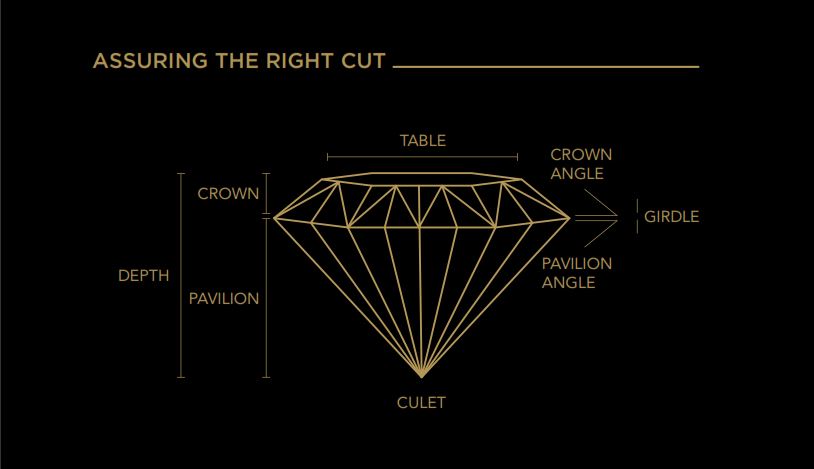

There are some basic pointers that are considered while cutting procedures :

Rough’s depth of colour

Rough’s depth of colour

Durability

Durability

Inclusions

Inclusions

Emerald crystal cutting is mostly a difficult procedure requiring accuracy and some related characteristics are :

A cut has to be designed in such a manner so that the fracture’s effect on the finished stone should be minimum.

A cut has to be designed in such a manner so that the fracture’s effect on the finished stone should be minimum.

As the nature of the gemstone is brittle, so , cut has to be done in accordance with protection against cutting, polish, setting and careless wear.

As the nature of the gemstone is brittle, so , cut has to be done in accordance with protection against cutting, polish, setting and careless wear.

Colour has prime importance so cut should maximize the effect of hue, saturation and tone.

Colour has prime importance so cut should maximize the effect of hue, saturation and tone.

Sometimes the colour tone is more intense on the surface as compared to the beneath layers so careful cut is required.

Sometimes the colour tone is more intense on the surface as compared to the beneath layers so careful cut is required.

Grade

| Grade | Description | Image |

|---|---|---|

| S1 | Very good colour, lustre and none/insignificant inclusions, loop clean |  |

| S2 | Very good colour, lustre and small inclusions |  |

| S3 | Very good colour, lustre, noticeable inclusions, eye clean |  |

| S4 | Very good colour, medium lustre, significant noticeable inclusions |  |

| S5 | Good colour, less lustre, more significant inclusions |  |